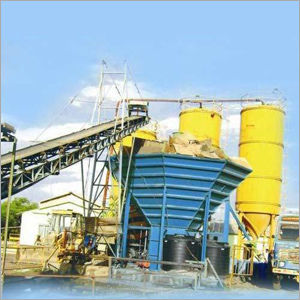

Storage Hopper Bolted Type

2000000 INR/Unit

Product Details:

- Product Type Storage Hopper Bolted

- General Use Industrial, Construction

- Material Other

- Type Concrete Mixing Plant

- Weight (kg) 20000 Kilograms (kg)

- Automatic Yes

- Power Source Electric

- Click to View more

X

Storage Hopper Bolted Type Price And Quantity

- 2000000 INR/Unit

- 1 Unit

Storage Hopper Bolted Type Product Specifications

- Other

- Industrial, Construction

- Electric

- 20000 Kilograms (kg)

- Storage Hopper Bolted

- 400 Volt (v)

- Concrete Mixing Plant

- Yes

Product Description

Storage Hopper Bolted Type

Persistently marching in todays competitive market, our company is recognized as one of the well established manufacturers and suppliers of Storage Hopper Bolted Type. Being a quality driven organization, we are manufacturing this storage hopper in strict adherence with the international quality standards and norms. Our offered hoppers is known for its sturdy construction and user friendly design. Clients can avail this Storage Hopper Bolted Type from us as per their precise specifications and requirements.

Advanced Electric Operation

Our Storage Hopper Bolted Type utilizes a reliable electric power source at 400 volts, ensuring seamless automation and consistent performance. This advanced technology minimizes manual intervention and enhances overall productivity during concrete mixing operations.

Durable Construction for Industrial Demands

With its heavy-duty bolted design and a substantial 20,000 kg capacity, the hopper is engineered to withstand rigorous industrial and construction environments. It offers stability and durability, reducing maintenance requirements and supporting long-term usage.

Comprehensive Supply and Service

As a leading manufacturer, exporter, and supplier in India, we provide end-to-end solutions, including installation, maintenance, and expert support. Our service ensures that customers gain optimal value from their investment and enjoy reliable operation throughout project lifecycles.

FAQs of Storage Hopper Bolted Type:

Q: How does the Storage Hopper Bolted Type facilitate automatic concrete mixing?

A: The hopper uses an electric power source to automate material storage and transfer, integrating seamlessly with concrete mixing plants. This reduces manual labor and ensures consistent material flow for efficient mixing.Q: What are the main benefits of choosing this hopper for industrial or construction projects?

A: Key advantages include high durability, large storage capacity, reliable electric operation, and compatibility with automated concrete mixing systems. These features improve productivity while minimizing downtime and maintenance.Q: When is the ideal time to integrate the Storage Hopper Bolted Type into a project?

A: The hopper is best integrated during the initial setup of a concrete mixing plant or when upgrading existing facilities. Early installation ensures smooth workflow and reliable operation throughout the project.Q: Where can the Storage Hopper Bolted Type be used effectively?

A: It is designed for use in industrial and construction environments where large-scale concrete mixing is required, such as on building sites, infrastructure projects, and material production facilities.Q: What is the process for installing and commissioning the hopper?

A: Our team provides comprehensive installation services, including assembly of the bolted structures, electrical integration for automation, and testing to ensure all operational parameters meet project requirements.Q: How does the hopper contribute to safe and efficient operation?

A: The bolted construction ensures structural integrity while the automated workflow reduces human intervention, lowering safety risks and enhancing consistency during concrete mixing activities.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese