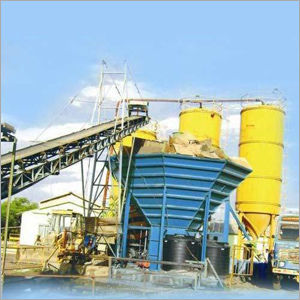

Readymix Concrete Batching Plant

1500000.00 INR/Unit

Product Details:

- Product Type RMC Plant With PAN Mixer

- General Use Industrial, Construction

- Material Other

- Computerized No

- Automatic Yes

- Voltage 440 Volt (v)

- Click to View more

X

Readymix Concrete Batching Plant Price And Quantity

- 1500000.00 INR/Unit

- 1 Unit

Readymix Concrete Batching Plant Product Specifications

- Industrial, Construction

- 440 Volt (v)

- Other

- No

- Yes

- RMC Plant With PAN Mixer

Product Description

Owing to our rich experience and skills in this respective sector, we have been successfully engaged in manufacturing a qualitative range of RMC Plant with PAN Mixer in the market. It is designed using supreme quality raw material and modern machinery at our unit in adherence with the international quality standards and norms. RMC Plant with PAN Mixer, which we are offering to our patrons is widely acknowledged in the market for its significant feature such as corrosion & rust resistance, sturdy construction and impeccable performance.

Features:

Features:

- Widely Demanded

- Optimum Quality

- Fine Finishing

- Long Service life

Product details

|

Power Source |

Electric |

|

Automation Grade |

Automatic |

|

Usage/Application |

Construction |

|

Brand |

GEPL |

|

Features |

Durable, Corrosion Resistant |

|

Voltage |

400 V |

|

Motor Power |

15 HP |

|

Frequency |

50-60 Hz |

|

Country of Origin |

Made in India |

|

Finish |

Color Coated |

Automatic Concrete Batching Simplified

Experience seamless concrete production with our automatic batching plant. The advanced system automates material measurement and mixing, optimizing the consistency and quality of the concrete blend. Ideal for construction and industrial sites, this automation reduces manual labor, ensuring swift operations and dependable results time after time.

Export and Service Coverage Across India

We are recognized pioneers in manufacturing, supplying, and exporting batching plants throughout India. Our extensive service network ensures prompt installation and maintenance support, allowing every client to benefit from uninterrupted operations. Whether its a large infrastructure project or routine industrial use, our team offers tailored solutions for your site.

FAQs of Readymix Concrete Batching Plant:

Q: How does the automatic feature enhance the batching plants performance?

A: The automatic system streamlines the batching process by accurately weighing and mixing raw materials without manual intervention. This improves efficiency, reduces errors, and ensures consistent concrete quality, making it ideal for industrial and construction applications.Q: What is the main process involved in operating the readymix concrete batching plant?

A: The process begins with feeding raw materials into hoppers, followed by automated weighing, mixing, and discharge. The plant operates at 440 volts, ensuring high-capacity production suited for demanding projects without requiring computerized control.Q: When is the optimal time to use this batching plant in a construction project?

A: The plant is best utilized during large-scale concrete pours, foundation works, or situations where uniform concrete quality and rapid production are crucial for project timelines.Q: Where can customers access export, supply, or service support across India?

A: Customers can reach out to our service centers located throughout India for export inquiries, supply orders, installation, and maintenance support. Our network is designed to provide reliable and prompt assistance wherever your site may be.Q: What are the benefits of using a readymix concrete batching plant compared to traditional mixing methods?

A: It offers improved production speed, higher consistency in concrete quality, reduced labor costs, and minimal material wastage. Automatic batching also diminishes human error, contributing to the overall reliability and efficiency of construction works.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese