Radial Conveyor for In-line Bin Feeder

500000.00 INR/Unit

Product Details:

- General Use Industrial, Construction

- Material Other

- Computerized No

- Automatic No

- Power Source Electric

- Color Customized

- Click to View more

X

Radial Conveyor for In-line Bin Feeder Price And Quantity

- 500000.00 INR/Unit

- 1 Unit

Radial Conveyor for In-line Bin Feeder Product Specifications

- Industrial, Construction

- No

- Customized

- Other

- Electric

- No

Product Description

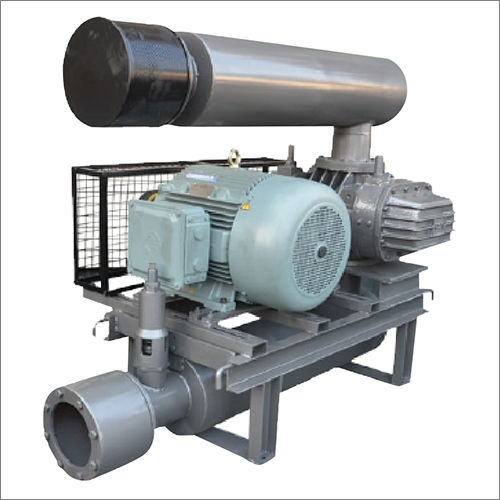

The Radial Conveyor for In-line Bin Feeder is designed to efficiently transport bulk materials like aggregates and sand from storage bins to batching plants. It features a rotating radial arm that delivers materials precisely to in-line bins, optimizing space and workflow. Capacities vary based on model, typically handling several tons per hour. Key components include the conveyor belt, radial arm, motor, support structure, and control system. Widely used in concrete batching, construction, and mining industries, it enhances material handling efficiency, reduces manual labor, and ensures continuous, accurate feeding for smooth production.

Versatile Industrial Solution

Our radial conveyor for in-line bin feeders is engineered for demanding industrial and construction environments. It provides smooth and consistent material flow, making it ideal for operations that need efficient bulk handling. With customizable color options and sturdy design, this conveyor meets diverse project needs while ensuring long-term reliability.

Trusted Indian Manufacturing and Export

We are a leading manufacturer, exporter, service provider, and supplier based in India. Our radial conveyors are produced using quality materials, precise processes, and stringent quality controls, guaranteeing exceptional performance. Customers worldwide benefit from our commitment to delivering dependable material handling solutions tailored to their specifications.

FAQs of Radial Conveyor for In-line Bin Feeder:

Q: How is the Radial Conveyor for In-line Bin Feeder typically used in industrial and construction settings?

A: This conveyor is used to transfer bulk materials from bins to desired locations during various stages of production or construction. It facilitates continuous feed, increases efficiency, and streamlines operations by automating material movement, reducing manual labor and time.Q: What is the process for installing a Radial Conveyor for In-line Bin Feeder at my facility?

A: Installation involves site preparation, equipment unloading, assembling conveyor sections, aligning with bin feeders, and connecting to the electric power source. Our team provides support throughout the process to ensure proper and safe setup at your location.Q: When is it beneficial to choose a non-computerized, non-automatic radial conveyor system?

A: Opting for a non-computerized, manually controlled conveyor is advantageous when simplicity, reliability, and cost-effectiveness are priorities. It is ideal for projects where advanced automation isnt mandatory but consistent performance and ease of operation are essential.Q: Where are these radial conveyors manufactured and shipped from?

A: All our radial conveyors are manufactured in India using high-grade materials and advanced processes. We export and supply them to customers worldwide, ensuring prompt delivery and dedicated after-sales support.Q: What are the main benefits of using an electrically powered radial conveyor for in-line bin feeding?

A: Electrically powered radial conveyors offer consistent operational efficiency, low maintenance requirements, and improved workplace safety. They are environmentally friendly and can be customized to fit specific requirements, enhancing productivity in demanding industrial and construction environments.Q: Can I request a customized color for my radial conveyor system?

A: Yes, we offer color customization to suit your facilitys aesthetic preferences or brand guidelines, ensuring seamless integration with existing equipment and operational spaces.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese